Technical Information

Applications

Clover Gate Valve Anchor Legs are used for restraining axial thrust forces.

A range of Clover Gate Valves include integral mounting points in the underside of the valve body to facilitate proprietary bolt on ductile iron anchor legs for casting into ‘cast-in-situ’ concrete anchor block under the valve.

Features and Benefits

| Features | Benefits |

| 10-year manufacturers’ warranty | Confidence of the highest quality valves, backed by a 10-year manufacturer’s warranty |

| Suitable for a range of Clover Resilient Seat Gate Valves | Compatibility and quality are assured, resulting in an easy to install solution |

| Reduced weight design | Safer and easier installation |

| Local inventory available | Fast and flexible supply to meet project demands |

| Thermally bonded polymeric coating | Long-term corrosion resistance and performance |

| 316 Stainless Steel Fasteners | Long-term corrosion resistance and performance |

Compliance

- AS/NZS2638.2 “Gate valves for waterworks purposes – Resilient seated”

- AS1831 “Ductile cast iron”

- AS/NZS4158 “Thermal-bonded polymeric coatings on valves and fittings for water industry purposes”

Product & Watermark Certification

Clover Gate Valve Anchor Legs are manufactured for compatibility with our range of independently third-party certified gate valves to AS/NZS2638.2 “Gate valves for waterworks purposes – Resilient seated”.

Accreditation body: Australian Certification Services – 25731

WSAA Product Appraisal

The Clover resilient seat gate valve range is independently appraised and recommended by the Water Services Association of Australia (WSAA);

- Product Appraisal 11/21

Diameter Range

Clover Gate Valve Anchor Legs are compatible with the following Clover Gate Valves featuring integral mounting points up to and including DN150;

- Double Flange PN16

- Double Socket PN16

- Double Spigot PN16

- Gripper Valve PN16

Pressure

Clover Gate Valve Anchor Legs are designed to provide in-line axial thrust restraint for suitable Clover Resilient Seat Gate Valves with a nominal pressure range of PN16 (1,600kPa).

Clover Resilient Seat Gate Valve Anchor Legs are not recommended for use on alternate valve types or brands.

Coating

Clover Gate Valve Anchor Legs are manufactured with a thermally bonded polymeric coating for long life corrosion protection.

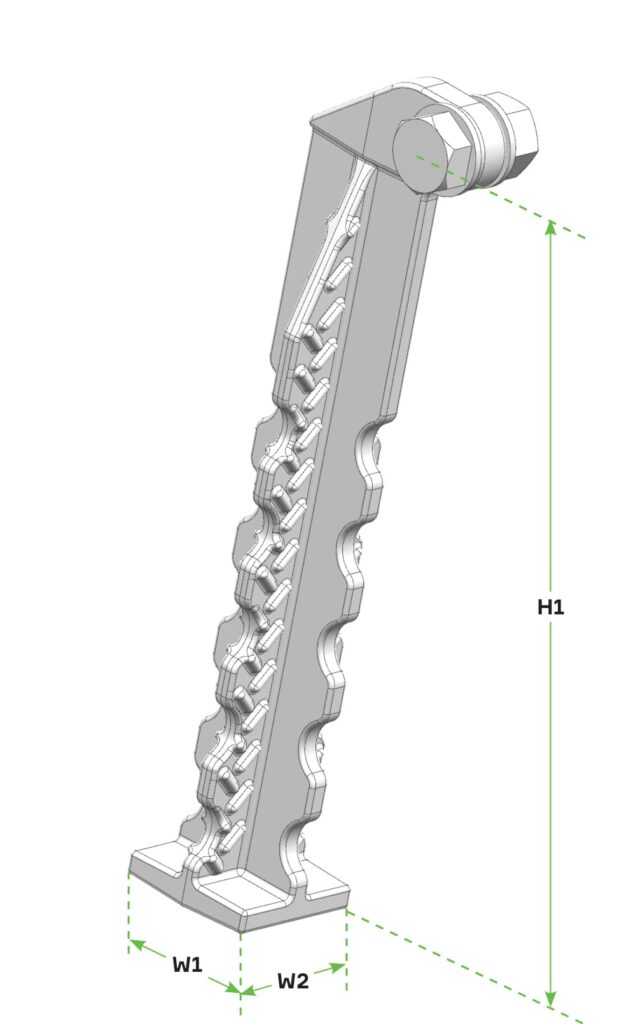

| Specifications | Sym | Units | |

| Height | H1 | mm | 277 |

| Base Height | H2 | mm | 7 |

| Base Width – Side | W1 | mm | 42 |

| Base Width – Front | W2 | mm | 54 |

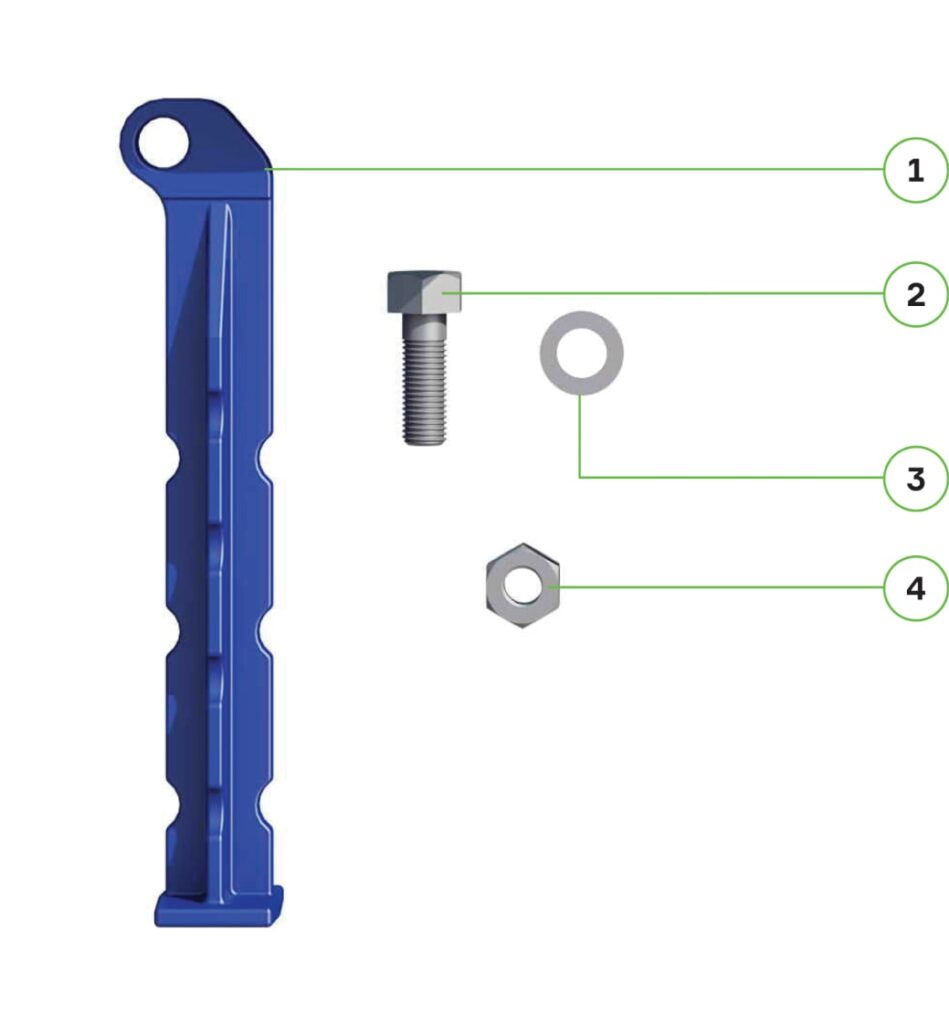

| Item | Part Name | Material |

| 1 | Anchors | Ductile Iron GGG50 |

| 2 | M16 Bolts | Stainless Steel 316 |

| 3 | M16 Washers | Stainless Steel 316 |

| 4 | M16 Nuts | Stainless Steel 316 |

Pressure

| Nominal Pressure (PN) | Allowable Operating Pressure (AOP) | Maximum Allowable Operating Pressure (MAOP) | Allowable Site Test Pressure (ASTP) |

| 16 | 1,600 kPa | 1,920 kPa | 2,000 kPa |

Mechanical Properties – Ductile Iron

| Property | Value & Unit |

| Ultimate tensile strength (Minimum) | 500MPa |

| Elongation (Minimum) | 7% |

| Density (Specific Gravity) | 7.1 |

Mechanical Properties - Coating

| Property | Value & Unit |

| External Surface | 300 Microns |

Installation Training

Clover’s in-house engineering team provides a range of training, accreditation and technical support services.

The Clover Academy installation training course provides installers with important information relating to the correct handling, installation, testing, maintenance and repair of Clover pipe systems and products.

Contact the Clover engineering team to discuss scheduling a training program.

Technical Support

Clover’s in-house engineering team combines specialist technical knowledge, creative thinking and on-the-job experience, to offer our clients a range of project planning and consultation services.

From recommendations on product innovations, to crafting complex end-to-end solutions, our collaborative approach bridges the gap between contractors, authorities and suppliers. The only Australian provider able to offer clients the full product suite, Clover offers unbiased, strategic insights that always consider the bigger picture.

From initial planning, to onsite training and technical assistance, we offer input across every stage of your project’s timeline. Our contribution continues beyond the project design, and we remain accessible for ongoing changes and developments over the course of each project.

We work with contractors, asset managers, local councils and government, developers and other pipeline professionals to specify bespoke product solutions. By engaging our team of engineers, you gain access to unparalleled product knowledge and expertise.