Technical Information

Applications

Corrugated structured wall polyethylene pipes and fittings offer effective drainage solutions and are suitable for non-pressure and low-head applications.

Typical applications include:

- Gravity stormwater and drainage pipelines

- Gravity sewer mains and sewer chamber riser

- Culverts

- Retention systems

- Pipeline rehabilitation and relining

- Rural and agricultural

- Ventilation ducting

- Low head water transfer

- Leachate gathering

- Buried and above ground

Features and Benefits

| Features | Benefits |

| Light weight design | Polyethylene corrugated pipes are lightweight, making them easy to handle, transport, and install. This makes installation faster and more cost-effective. |

| Australian Made | Australian-made products guarantee that the products meet strict Australian standards for quality. Reflecting a commitment to supporting local industries and reducing environmental impacts. |

| Long lasting performance | The durability of polyethylene is a key asset, providing it the ability to resist heavy handling and installation stresses without compromising its integrity or performance. This ensures that the product remains effective over long periods, even in demanding conditions. |

| Simplified Connection System | The design includes an effective rubber ring joint system that facilitates easy assembly and secure jointing. Designed to meet strict Australian Standards requirements for effective sealing and resistance to root intrusion, the seal simplifies installation. |

| Eco-friendly materials and manufacturing | Clover polyethylene corrugated pipes are 100% recyclable and are notable for their low embodied energy, contributing significantly to its environmental benefits. Choosing materials with lower embodied energy helps reduce the overall carbon footprint of construction projects, aligning with sustainability goals and regulations. |

| Adaptability to Ground Conditions | The inground performance of polyethylene is exceptional, exhibiting a high tolerance to deformation and the ability to accommodate ground movements. This resilience ensures that the infrastructure remains functional and reliable over time |

Australian Standards

Corrugated polyethylene pipe and fittings supplied by Clover are manufactured and independently third party certified to the following standards:

- AS/NZ5065 “Polyethylene and polypropylene pipes and fittings for drainage and sewerage applications”

- AS1646 “Elastomeric seals for waterworks purposes”

Diameter Range

Clover corrugated structured wall polyethylene pipes are available in diameters ranging from DN225 to DN1050.

* Larger diameters up to DN2000 available on request.

Stiffness

The ring stiffness of a flexible pipe measures its strength against various pressures such as soil load, external water pressure, internal vacuum, vehicle weight, and loads during construction. This stiffness is tested in labs and is shown in units of N/m/m, based on standards AS/NZS 2566.1 and AS/NZS 1462.22.

Clover corrugated structured wall polyethylene pipes exceed 8,000N/m/m (Classified SN8 in AS/NZS5065).

Dimensions

| Nominal Diameter | Minimum Mean Pipe Inside Diameter* | Stockcode | Nominal Length (m) | Approximate Pipe Mass (kg/m) | Stiffness (Nm) |

| 225 | 216 | PSTORMP0225 | 6 | 3.0 | 8,000 |

| 300 | 292 | PSTORMP0300 | 6 | 5.0 | 8,000 |

| 375 | 361 | PSTORMP0375 | 6 | 8.0 | 8,000 |

| 450 | 432 | PSTORMP0450 | 6 | 12.0 | 8,000 |

| 525 | 515 | PSTORMP0525 | 6 | 16.5 | 8,000 |

| 600 | 584 | PSTORMP0600 | 6 | 21.0 | 8,000 |

| 750 | 723 | PSTORMP0750 | 6 | 44.0 | 8,000 |

| 900 | 864 | PSTORMP0900 | 6 | 33.0 | 8,000 |

| 1050 | 1008 | PSTORMP1050 | 6 | 58.0 | 8,000 |

* Based on AS/NZS5065 Type B ID series corrugated pipe dimensions – varies by manufacturer

Lengths

Clover corrugated structured wall polyethylene pipes are supplied in standard 6m nominal lengths.

Pipes can be simply cut to length on site and re-joined for shorter length adjustments or connections.

Joints

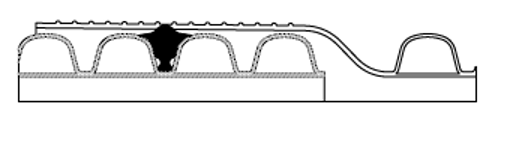

Clover corrugated structured wall polyethylene pipes incorporate an advanced spigot and socket elastomeric joint, designed to meet the requirements set by AS/NZS5065. Each pipe is supplied with a standard elastomer gasket for simple and effective jointing.

The elastomeric gasket is positioned in the second last trough near the spigot end and compresses to create a seal as the spigot is inserted into the socket. This innovative design enables installers to cut the pipe at any point along its length and still effectively form a joint.

EPDM gaskets comply with the requirements of AS1646 “Elastomeric seals for waterworks purposes”.

Fittings

Clover offer a full set of fittings to be used with our corrugated polyethylene drainage pipes, providing a complete piping system. This includes bends, tees, junctions, end caps, couplings, plugs, reducers, saddles, and adaptors. These fittings meet the requirements of Australian Standard AS/NZS5065 “Polyethylene and polypropylene pipes and fittings for drainage and sewerage applications”.

Clover supplies a complete range of compatible fittings and accessories to compliment any pipeline solution. Contact Clover for additional technical and pricing information.

Chemical Resistance

Clover corrugated structured wall pipes and fittings are manufactured from polyethylene, ensuring outstanding durability against corrosive conditions in drainage environments. Polyethylene demonstrates high resilience to challenging underground environments including acid sulphate soils and saline groundwater.

Contact Clover Pipelines engineers for further guidance on suitability.

Properties

| Property | Units | Value |

| Density | kg/m³ | 960 |

| Circumferential Flexural Modulus (2mm/min) | MPa | >1000 |

| Creep ratio (2 years) | ||

| Circumferential Flexural Creep Modulus (2 years) | MPa | |

| Circumferential Flexural Creep Modulus (50 years) | MPa | |

| Pipe Ring Bending Stiffness | N/m/m | ≥ 8000 |

| Flexural Yield Stress | MPa | |

| Tensile Yield Stress (50mm/min) | MPa | 25 |

| Tensile Yield Strain (50mm/min) | ||

| Poisson’s Ratio | 0.40 | |

| Thermal Co-efficient of Linear Expansion | ||

| Shore D Hardness | ||

| Pipe – Allowable Long-Term Deflection | ||

| Pipe – Allowable Long-Term Ring Bending Strain |

Minimum cover heights

AS/NZS2566.1 “Buried flexible pipelines – structural design”

| Location | Minimum height of cover (m) |

| Not subject to vehicular loading | 0.30 |

| Subject to vehicular loading | |

| — Not in roadways | 0.45 |

| — In sealed roadways | 0.60 |

| — In unsealed roadways | 0.75 |

| Pipes in embankment conditions or subject to construction equipment loading | 0.75 |

Installation

Installation methods for the Clover corrugated structured wall polyethylene pipe system are generally in accordance with AS/NZS2033 “Installation of polyethylene pipe systems” and AS/NZS2566.2 “Buried flexible pipelines – Installation”. The standards specify the requirements for the installation of buried flexible pipelines with structural design in accordance with AS/NZS2566.1 “Buried flexible pipelines – Design”.

The key to ensuring the pipes are installed successfully lies in selecting and properly compacting the embedment material, which is in direct contact with the pipes. This material should be granular and easy to compact, with crushed rock, aggregate, and graded sand being common choices. For detailed information on selecting and using various embedment materials, refer to Appendices ‘G’ and ‘H’ in the AS/NZS2566.2 “Buried flexible pipelines – Installation” standard.

Testing & Commissioning

Testing and commissioning methods for corrugated structured wall polyethylene pipe system are generally in accordance with AS/NZS2033 “Installation of polyethylene pipe systems” and AS/NZS2566.2 “Buried flexible pipelines – Installation”. The standards specify the requirements for the field-testing and commissioning of buried flexible pipelines with structural design in accordance with AS/NZS2566.1 “Buried flexible pipelines – Design”.

Installation Training

Clover’s in-house engineering team provides a range of training, accreditation and technical support services.

The Clover Academy installation training course provides installers with important information relating to the correct handling, installation, testing, maintenance and repair of Clover pipe systems and products.

Contact the Clover engineering team to discuss scheduling a training program.

Technical Support

Clover’s in-house engineering team combines specialist technical knowledge, creative thinking and on-the-job experience, to offer our clients a range of project planning and consultation services.

From recommendations on product innovations, to crafting complex end-to-end solutions, our collaborative approach bridges the gap between contractors, authorities and suppliers. The only Australian provider able to offer clients the full product suite, Clover offers unbiased, strategic insights that always consider the bigger picture.

From initial planning, to onsite training and technical assistance, we offer input across every stage of your project’s timeline. Our contribution continues beyond the project design, and we remain accessible for ongoing changes and developments over the course of each project.

We work with contractors, asset managers, local councils and government, developers and other pipeline professionals to specify bespoke product solutions. By engaging our team of engineers, you gain access to unparalleled product knowledge and expertise.

Life Expectancy

When installed and operated in accordance with the manufacturers guidelines this pipe system can be expected to perform well in excess of 100 years before major rehabilitation is required.