Clover Gunmetal Tapping Bands – WSAA Appraisal

PDF, 226.6K

Options available to suit a wide range of pipe materials including PVC, Polyethylene, GRP and AC.

Manufactured and certified to AS/NZS4793 & AS/NZS4129.

Dezincification resistant (DZR) Gunmetal Body featuring a full-circle design with positive stop.

Applications

Clover gunmetal tapping bands are suitable for use in pressurised water supply applications. Tapping bands allow for the connection of water service pipes to a pipeline.

Typical applications include;

Clover gunmetal tapping bands are designated for use on flexible pipelines (Type F). Type F tapping bands are suitable for use with rigid pipes of the same outside diameter.

Series 2 – OPVC, MPVC, UPVC, GRP & AC Pipelines

Size Range: DN100 – DN450

Suitable for use on the following pipeline materials;

Gunmetal tapping bands are not recommended for use with DICL/CICL pipe unless appropriate insulation is installed to counteract potential bi-metallic corrosion.

Series 1 – OPVC, MPVC, UPVC & Steel Pipelines

Size Range: DN50 – DN375

Suitable for use on the following pipeline materials;

Polyethylene Pipelines

Size Range: DN63-DN400

Suitable for use on the following pipeline materials;

Features and Benefits

| Features | Benefits |

| Full circle design with positive stop | Prevents over-tightening during installation, which can be crucial for avoiding damage to the pipe |

| Dezincification resistant (DZR) gunmetal body and 316 stainless steel fasteners | Long-term corrosion resistance and performance |

| Local inventory available | Fast and flexible supply to meet project demands |

Compliance

Product & Watermark Certification

Clover gunmetal tapping bands are manufactured and independently third party certified to AS/NZS4793 “Mechanical tapping bands for waterworks purposes” and AS/NZS4129 “Fittings for polyethylene (PE) pipes for pressure applications”

Accreditation body: Australian Certification Services – 3003

WSAA Product Appraisal

Clover gunmetal tapping bands are independently appraised and recommended by the Water Services Association of Australia (WSAA);

Suitability for Use with Potable Water (AS/NZS4020 Compliance)

Clover gunmetal tapping bands are suitable for potable water applications and comply with the requirements of AS/NZS4020 “Testing of products for use in contact with drinking water”.

WSAA Purchase Specification

Clover gunmetal tapping bands comply with the requirements of the following WSAA Purchase Specification(s):

Diameter Range

Clover gunmetal tapping bands are manufactured with nominal diameters ranging from DN50 to DN450.

For tapping bands with larger diameters please contact Clover for additional technical and pricing information.

Pressure

Clover gunmetal tapping bands are manufactured with a standard nominal pressure range of PN16 (1,600kPa).

| Item | Part Name | Material |

| 1 | Body | Gunmetal |

| 2 | Gasket | Nitrile Rubber (NBR) AS1646 |

| 3 | Bolt | 316 Stainless Steel |

| 4 | Hex Nut | 316 Stainless Steel with Anti-Seize Coating |

| Product Code | ||||||

| DN | OD | 20BSP | 25BSP | 32BSP | 40BSP | 50BSP |

| 100 | 122 | TCBAC100020 | TCBAC100025 | TCBAC100032 | TCBAC100040 | TCBAC100050 |

| 150 | 177 | TCBAC150020 | TCBAC150025 | TCBAC150032 | TCBAC150040 | TCBAC150050 |

| 200 | 232 | TCBAC200020 | TCBAC200025 | TCBAC200032 | TCBAC200040 | TCBAC200050 |

| 225 | 259 | TCBAC225020 | TCBAC225025 | TCBAC225032 | TCBAC225040 | TCBAC225050 |

| 250 | 286 | TCBAC250020 | TCBAC250025 | TCBAC250032 | TCBAC250040 | TCBAC250050 |

| 300 | 345 | TCBAC300020 | TCBAC300025 | TCBAC300032 | TCBAC300040 | TCBAC300050 |

| 375 | 426 | TCBAC375020 | TCBAC375025 | TCBAC375032 | TCBAC375040 | TCBAC375050 |

| 450 | 507 | TCBAC450020 | TCBAC450025 | TCBAC450032 | TCBAC450040 | TCBAC4500050 |

| Product Code | ||||||

| DN | OD | 20BSP | 25BSP | 32BSP | 40BSP | 50BSP |

| 50 | 60 | TCBP050020 | TCBP050025 | – | – | – |

| 80 | 89 | TCBP080020 | TCBP080025 | TCBP080032 | TCBP080040 | TCBP080050 |

| 100 | 114 | TCBP100020 | TCBP100025 | TCBP100032 | TCBP100040 | TCBP100050 |

| 150 | 160 | TCBP150020 | TCBP150025 | TCBP150032 | TCBP150040 | TCBP150050 |

| 200 | 225 | TCBP200020 | TCBP200025 | TCBP200032 | TCBP200040 | TCBP200050 |

| 225 | 250 | TCBP225020 | TCBP225025 | TCBP225032 | TCBP225040 | TCBP225050 |

| 250 | 280 | TCBP250020 | TCBP250025 | TCBP250032 | TCBP250040 | TCBP250050 |

| 300 | 315 | TCBP300020 | TCBP300025 | TCBP300032 | TCBP300040 | TCBP300050 |

| 375 | 400 | TCBP375020 | TCBP375025 | TCBP375032 | TCBP375040 | TCBP375050 |

| Product Code | ||||||

| DN | OD | 20BSP | 25BSP | 32BSP | 40BSP | 50BSP |

| 63 | 63 | TCBPE063020 | TCBPE063025 | – | – | – |

| 90 | 90 | TCBPE090020 | TCBPE090025 | TCBPE090032 | TCBPE090040 | TCBPE090050 |

| 125 | 125 | TCBPE125020 | TCBPE125025 | TCBPE125032 | TCBPE125040 | TCBPE125050 |

| 160 | 160 | TCBPE160020 | TCBPE160025 | TCBPE160032 | TCBPE160040 | TCBPE160050 |

| 180 | 180 | TCBPE180020 | TCBPE180025 | TCBPE180032 | TCBPE180040 | TCBPE180050 |

| 225 | 225 | TCBPE225020 | TCBPE225025 | TCBPE225032 | TCBPE225040 | TCBPE225050 |

| 250 | 250 | TCBPE250020 | TCBPE250025 | TCBPE250032 | TCBPE250040 | TCBPE250050 |

| 280 | 280 | TCBPE280020 | TCBPE280025 | TCBPE280032 | TCBPE280040 | TCBPE280050 |

| 315 | 315 | TCBPE315020 | TCBPE315025 | TCBPE315032 | TCBPE315040 | TCBPE315050 |

| 400 | 400 | TCBPE400020 | TCBPE400025 | TCBPE400032 | TCBPE400040 | TCBPE400050 |

End Connections

Clover gunmetal tapping bands are available with tapped outlet connections with ¾”, 1”, 1 ¼”, 1 ½” or 2” BSP tapped parallel thread to AS ISO 7.1 “Pipe threads where pressure-tight joints are made on the threads Dimensions, tolerances and designation”.

Pressure

| Nominal Pressure (PN) | Allowable Operating Pressure (AOP) | Maximum Allowable Operating Pressure (MAOP) | Allowable Site Test Pressure (ASTP) |

| 16 | 1,600 kPa | 1,920 kPa | 2,000 kPa |

Maximum Operating Temperature

40°

Options & Accessories

Extensive local inventory of a wide range of associated ferrules, ball valves and accessories is available.

Contact Clover for further information.

Installation, Operation & Maintenance

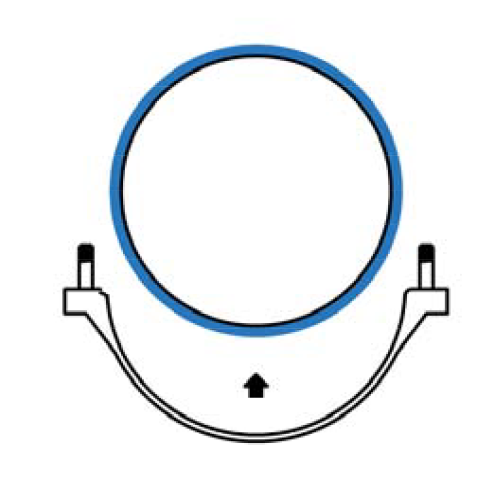

Fig 1. |

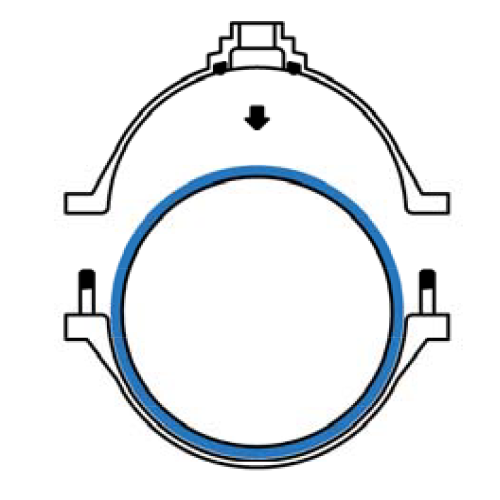

Fig 2. |

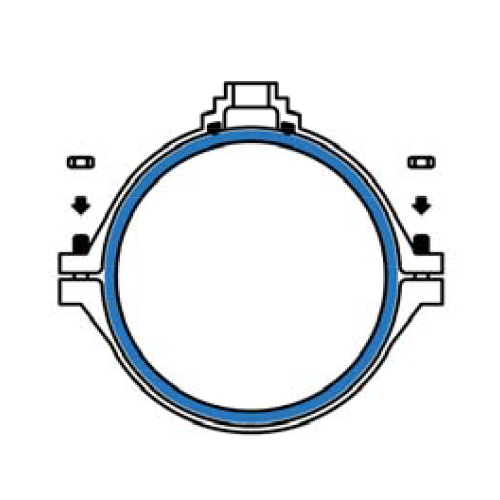

Fig 3. |

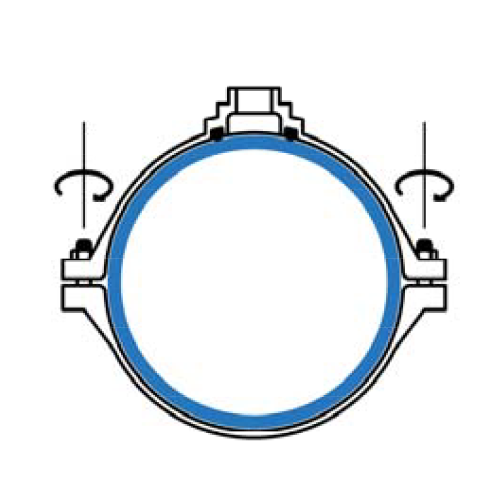

Fig 4. |

Tapping Band: Gunmetal – Installation Manual – Reference Guide

PDF, 233.0K

Installation Training

Clover’s in-house engineering team provides a range of training, accreditation and technical support services.

The Clover Academy installation training course provides installers with important information relating to the correct handling, installation, testing, maintenance and repair of Clover pipe systems and products.

Contact the Clover engineering team to discuss scheduling a training program.

Technical Support

Clover’s in-house engineering team combines specialist technical knowledge, creative thinking and on-the-job experience, to offer our clients a range of project planning and consultation services.

From recommendations on product innovations, to crafting complex end-to-end solutions, our collaborative approach bridges the gap between contractors, authorities and suppliers. The only Australian provider able to offer clients the full product suite, Clover offers unbiased, strategic insights that always consider the bigger picture.

From initial planning, to onsite training and technical assistance, we offer input across every stage of your project’s timeline. Our contribution continues beyond the project design, and we remain accessible for ongoing changes and developments over the course of each project.

We work with contractors, asset managers, local councils and government, developers and other pipeline professionals to specify bespoke product solutions. By engaging our team of engineers, you gain access to unparalleled product knowledge and expertise.

Clover Gunmetal Tapping Bands – WSAA Appraisal

PDF, 226.6K

Get in touch with our team for additional information on product pricing, technical data, project support and more.

Get in touch with our team so we can support the planning, source, and supply of your next project.

We endeavour to reply within 1 business day.

Thanks for getting in touch, we will respond as quickly as possible.

If you have an urgent matter, please call your nearest Clover branch.