Technical Information

Applications

Clover Polyethylene Restraint Flange Adaptors are suitable for pressure and non-pressure water supply and sewerage applications and can be installed buried or above ground.

Typical applications include;

- Potable and recycled water supply

- Irrigation and raw water

- Gravity and sewer rising mains

- Stormwater and drainage

- Buried and above ground

Features and Benefits

Clover Polyethylene Restraint Flange Adaptors feature many advantages over other pipeline materials.

| Features | Benefits |

| Provides axial thrust restraint | When installed on a polyethylene pipe the product provides axial thrust restraint, eliminating the need for concrete thrust blocks. |

| Tough material | High strength ductile iron body allowing it to endure irregular operating conditions and the demands of handling in the field. |

| Simple and fast installation | The product can be installed quickly and effectively under all weather conditions without the need for polyethylene welding. |

| Long-term corrosion resistance | Clover polyethylene restraint flange adaptors are supplied with a thermally bonded polymeric coating for long life corrosion protection. |

| Long Term Performance | Proven long-term performance and maintenance free operation. |

| Joint Deflection | Each joint can be deflected up to 2 degrees* . |

* Refer to the joint deflection table below for specifications

Compliance

Clover polyethylene restraint flange adaptors are manufactured in compliance with the following standards;

- EN12842 “Ductile iron fittings for PVC-U or PE piping systems — Requirements and test methods”

- AS/NZS4087 “Metallic flanges for waterworks purposes”

- AS/NZS4158 “Thermal-bonded polymeric coatings on valves and fittings for water industry purposes”

- AS1646 “Elastomeric seals for waterworks purposes”

- AS/NZS4020 “Testing of products for use in contact with drinking water”

WSAA Product Appraisal

The polyethylene restraint joint used in this product range is independently appraised and recommended by the Water Services Association of Australia (WSAA);

- Product Appraisal 11/21 (DN90 to DN315)

WSAA Purchase Specification

Clover polyethylene restraint flange adaptors comply with the requirements of the following Water Services Association of Australia (WSAA) purchase specification(s);

- WSA PS245 – Ductile Iron Fittings with Restrained Flexible Joints for Polyethylene Pipe of Nominal Sizes 90 to 1000 in Pressure Applications – Water Supply and Sewerage.

Suitability for Use with Potable Water (AS/NZS4020 Compliance)

Clover polyethylene restraint flange adaptors are suitable for potable water applications and comply with AS/NZS4020 “Testing of products for use in contact with drinking water”.

Diameter Range

Clover polyethylene restraint flange adaptors are manufactured with nominal diameters ranging from DN63 to DN315.

Pressure

Clover polyethylene restraint flange adaptors are manufactured with a standard nominal pressure range of PN16 (1,600kPa).

Pipe stiffener inserts are recommended for PE100 pipes ≤ SDR 17, i.e. PN10 or lower.

DN63 - DN180

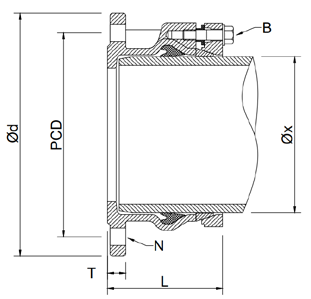

| Specifications | SYM | UNITS | DN 63 |

DN 75 |

DN 90 |

DN 110 |

DN 125 |

DN 160 |

DN 180 |

| Pipe Outside Diameter | Øy | mm | 63 | 75 | 90 | 110 | 125 | 160 | 180 |

| Flange (AS4087 B5) | DN | mm | 50* | 65* | 80 | 100* | 100* | 150 | 150 |

| Pressure Nominal | PN | Nom | 16 | 16 | 16 | 16 | 16 | 16 | 16 |

| Length | L | mm | 90 | 95 | 100 | 100 | 100 | 125 | 132 |

| Flange Outside Diameter | Ø d | mm | 150 | 165 | 185 | 215 | 215 | 280 | 280 |

| Pitch Circle Diameter | PCD | mm | 114 | 127 | 146 | 178 | 178 | 235 | 235 |

| Flange Bolt Holes | N | 4-Ø18 | 4-Ø18 | 4-Ø18 | 8-Ø22 | 8-Ø22 | 8-Ø18 | 8-Ø18 | |

| Flange Thickness | T | mm | 17 | 17 | 18 | 20 | 20 | 23 | 23 |

| Maximum Joint Deflection | O | deg | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| Restraint System Bolts | B | # x mm | 4 x M10 | 4 x M10 | 4 x M10 | 4 x M10 | 4 x M12 | 4 x M12 | 4 x M12 |

| Weight of Unit | W | kg | 4 | 5 | 6 | 7 | 8 | 11 | 12 |

| Product Code | PPSFA063 | PPSFA075 | PPSFA090 | PPSFA110 | PPSFA125 | PPSFA160 | PPSFA180 |

* AS2129 Table E Drilling Pattern

DN200 - DN315

| Specifications | SYM | UNITS | DN 200 |

DN 225 |

DN 250 |

DN 250 |

DN 280 |

DN 280 |

DN 315 |

| Pipe Outside Diameter | Øy | mm | 200 | 225 | 250 | 250 | 280 | 280 | 315 |

| Flange (AS4087 B5) | DN | mm | 200 | 200 | 200 | 250 | 225 | 250 | 300 |

| Pressure Nominal | PN | Nom | 16 | 16 | 16 | 16 | 16 | 16 | 16 |

| Length | L | mm | 138 | 142 | 225 | 160 | 225 | 170 | 190 |

| Flange Outside Diameter | Ø d | mm | 335 | 335 | 335 | 405 | 370 | 405 | 455 |

| Pitch circle Diameter | PCD | mm | 292 | 292 | 292 | 356 | 324 | 356 | 406 |

| Flange bolt holes | N | 8-Ø18 | 8-Ø18 | 8-Ø18 | 8-Ø22 | 8-Ø18 | 8-Ø22 | 12-Ø22 | |

| Flange Thickness | T | mm | 23 | 23 | 23 | 24 | 24 | 24 | 30 |

| Maximum joint deflection | O | deg | 1.7 | 1.7 | 1.7 | 1.7 | 1.7 | 1.7 | 1.7 |

| Restraint System Bolts | B | # x mm | 4 x M12 | 4 x M12 | 6 x M12 | 6 x M12 | 6 x M12 | 6 x M12 | 6 x M12 |

| Weight of Unit | W | kg | 18 | 20 | 27 | 27 | 33 | 29 | 46 |

| Product Code | PPSFA200 | PPSFA225200 | PPSFA250200 | PPSFA250 | PPSFA280225 | PPSFA280250 | PPSFA315 |

Joints

Clover polyethylene restraint flanges feature an EPDM rubber elastomeric joint. EPDM gaskets comply with the requirements of AS1646 “Elastomeric seals for waterworks purposes”.

Joint Deflection

Clover polyethylene restraint flange adaptors incorporate an integrated elastomeric gasket. Each pipe joint can be deflected allowing the installer to deflect the fitting during installation.

The maximum recommended joint deflection for each polyethylene restraint flange adaptors are provided below;

| Nominal Diameter (DN) | Maximum Joint Deflection (deg) |

| 63 – 180 | 2.0O |

| 200 – 315 | 1.7O |

Pressure

| Nominal Diameter (DN) | Nominal Pressure (PN) | Nominal Pressure (MPa) | Allowable Operating Pressure (AOP) | Maximum Allowable Operating Pressure (MAOP) | Allowable Site Test Pressure (ASTP) |

| 63 – 315 | 16 | 1.6 MPa | 1.6 MPa | 1.92 MPa | 2.0 MPa |

Temperature

The maximum recommended service temperature for use with this product is 40°C.

Options

Clover polyethylene restraint flange adaptors can be supplied with;

- Alternate flange drillings

- 316 Stainless steel tensile restraint ring

Contact Clover for further information.

Mechanical Properties

| Property | Value & Unit |

| Ultimate tensile strength (Minimum) | 500MPa |

| Elongation (Minimum) | 7% |

Flange Assembly

Flange assembly should be carried out in accordance with Water Services Association of Australia (WSAA) guidelines WSA-109 ” Flanged Gaskets and O-rings” guidelines. General flange installation guidelines can also be found on the Clover website –

https://www.cloverpipe.com.au/downloads/flange-assembly-installation-guide

Installation Training

Clover’s in-house engineering team provides a range of on-site training, accreditation and technical support services.

The Clover Academy installation training course provides installers with important information relating to the correct handling, installation, testing, maintenance and repair of Clover pipe systems and products.

Contact the Clover engineering team to discuss scheduling a training program.

Technical Support

Clover’s in-house engineering team combines specialist technical knowledge, creative thinking and on-the-job experience, to offer our clients a range of project planning and consultation services.

From recommendations on product innovations, to crafting complex end-to-end solutions, our collaborative approach bridges the gap between contractors, authorities and suppliers. The only Australian provider able to offer clients the full product suite, Clover offers unbiased, strategic insights that always consider the bigger picture.

From initial planning, to onsite training and technical assistance, we offer input across every stage of your project’s timeline. Our contribution continues beyond the project design, and we remain accessible for ongoing changes and developments over the course of each project.

We work with contractors, asset managers, local councils and government, developers and other pipeline professionals to specify bespoke product solutions. By engaging our team of engineers, you gain access to unparalleled product knowledge and expertise.