How Zinalium extends pipe life and reduces installation cost

July 26, 2021

By: Mark Laws

General Manager

Introducing Zinalium: the next-generation protection system that extends the life and performance of ductile iron pipe in ground.

At Clover, we’re proud to actively embrace new ideas and innovations. We strive to push the envelope in pipeline systems and products. That’s why we’re excited to introduce a new suite of Zinalium-coated ductile iron pipe products.

What is Zinalium®?

Created and developed by our exclusive distribution partner—PAM Saint-Gobain—Zinalium® is a unique protective coating that can be applied to ductile iron pipe to extend pipe life and performance in ground.

The name ‘Zinalium’ represents the coating’s chemical makeup: it is a combination of zinc (85%) and aluminium (15%).

A Zinalium-coated pipe consists of three components:

- the Zinalium coating

- a synthetic resin pore sealer, and

- the ductile iron pipe itself

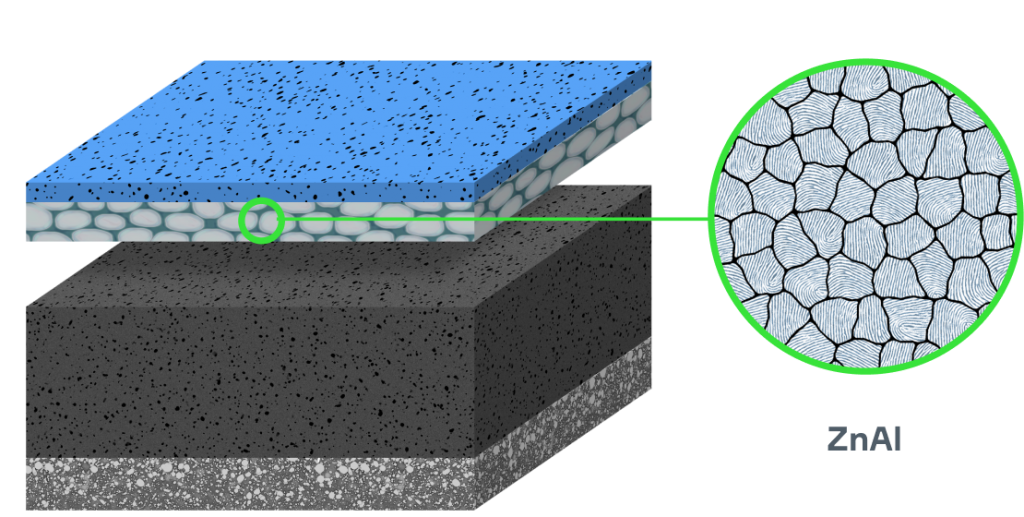

1. About the Zinalium coating

The Zinalium coating is melted onto the as-cast surface of the pipe by high-pressure air. The alloying ensures the intimate mixing of zinc and aluminium—and the resulting microstructure—optimises the distribution of the zinc in the coating for maximum corrosion protection. The minimum coating application thickness is 400g/m2.

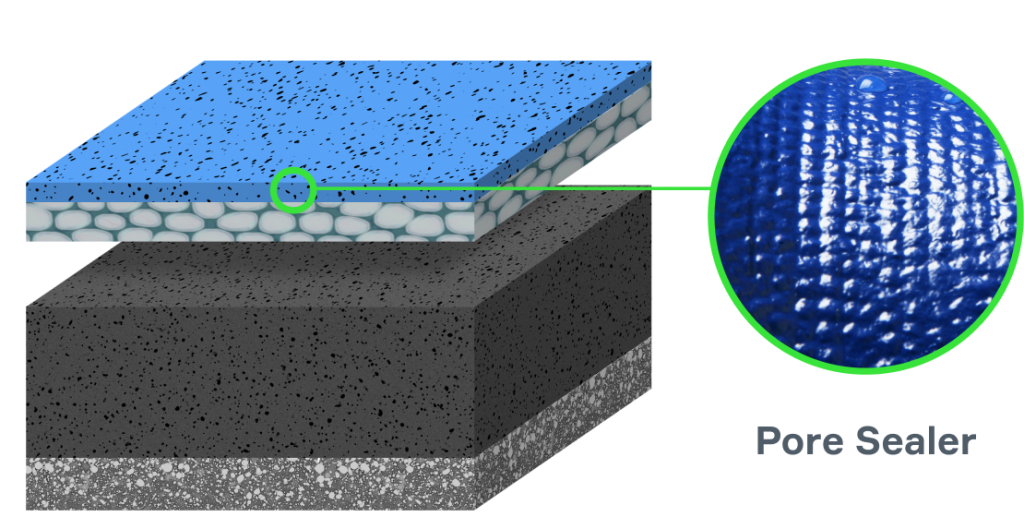

2. About the synthetic resin pore sealer

A synthetic epoxy pore sealer is applied to the as-sprayed zinc-aluminium coating to a minimum thickness of 100μm. This ensures the Zinalium coating is gradually exposed to the soil over time. The stepped exposure process ensures the zinc transforms into insoluble corrosion products slowly, creating a powerful layer of protection for the ductile iron pipe. Without the synthetic pore sealer, these vital corrosion products could be dissolved by water and moisture in the soil.

3. About the ductile iron pipe

PAM ductile iron pipe is globally renowned for long-term performance and maintenance free operation. It is also proven to endure irregular operating conditions and the demands of handling in the field.

What is the benefit of Zinalium?

Zinalium® offers three benefits:

- It protects ductile iron pipe against the long-term impact of soil-based corrosive materials when pipes are installed in ground, thereby extending the pipe’s usage.

- It can ‘heal’ minor damages to the pipe, like scratches or nicks from third-party maintenance once the pipes are commissioned in ground.

- It eliminates the need for sleeving, improving efficiencies on site and contributing to shorter project timeframes.

How does Zinalium protect ductile iron pipe in corrosive conditions?

Once it’s installed in the ground, Zinalium provides ‘galvanic protection’ to ductile iron pipe.

Different metals adopt different electrode potentials and behaviours when exposed to various substances. ‘Galvanic protection’ occurs when two dissimilar metals are in close contact with one another—like zinc and aluminium—and react differently over time, or change due to reactions triggered by the materials around them.

Galvanic protection is a biphasic process. This means the protection provided by Zinalium is created during a process that consists of two distinct phases:

- The first phase occurs as zinc reacts to certain materials in the ground.

- The second phase occurs as the zinc ‘re-sets’ following a transformation triggered by properties in certain types of corrosive soil.

For example, when a zinc-coated ductile iron pipe is buried in the ground, the zinc galvanizes by coming into contact with aggressive soil. The soil triggers a slow transformation, where the zinc transitions into a variety of zinc-conversion products, like:

- Zinc oxides

- Zinc carbonates

- Zinc oxychlorides, and more.

The process involved in this transformation creates a stable, dense and binding layer, which takes up exactly the same space and fills all pores (or holes) that existed in the initial layer of zinc. Therefore, over time, it evenly covers the entire surface of the pipe.

Crucially, because the initial zinc layer is highly porous (allowing air, liquid and other materials to freely pass through it), the newly converted zinc-products are able to form without needing more room between the ductile pipe and the resin layer. This ensures the outside layer of the pipe—a semi-permeable blue epoxy resin, implemented for pore sealing—does not crack, swell or distend.

As the newly formed layer fills up the pores of the initial zinc layer, it binds with the other elements of the pipe very effectively to create a strong, protective barrier.

The pore sealer—or blue epoxy—is used to limit too much contact with the soil. This protection enables the zinc to transform into insoluble zinc crystals slowly. If no pore-sealer is used, these crystals could be dissolved by any water or moisture within the soil.

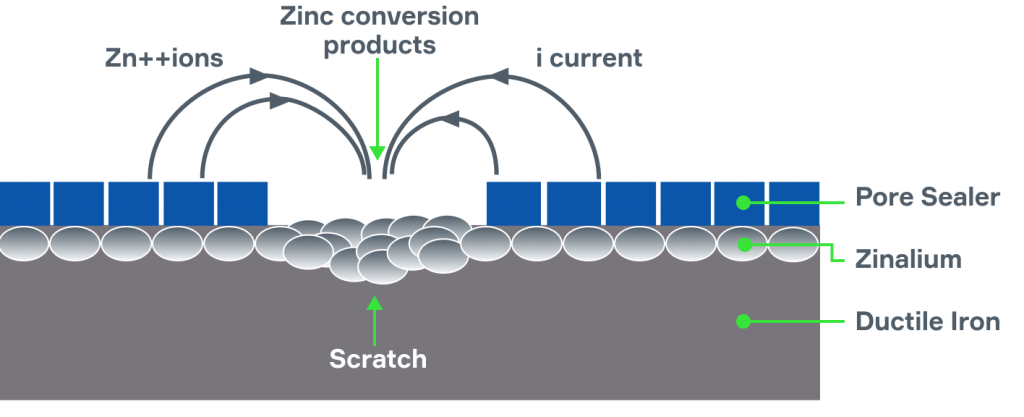

How does Zinalium ‘heal’ minor damages to the pipe?

Imagine a buried pipe is nicked by machinery or excavation equipment completing nearby maintenance. In this example, Zinalium coating can restore protection of the inner ductile iron pipe. This process is referred to as ‘healing’.

When part of the pipe’s external coating is damaged, the ductile iron becomes exposed. As a result of the exposure, zinc ions come into contact with certain chemicals.

Interested in seeing a real-world example of how Zinalium pipes can deliver significant benefits to your pipeline project?

Thanks to Zinalium, we were able to reduce the installation cost of the Edmondson Park Potable and Recycled Water Lead-In Project while also extending the service life of the pipes. And, best of all, the system will deliver reliable, high-quality water to residents and businesses in the area for decades to come.

Explore our case study to learn more here.

Looking to learn more about Zinalium and our exclusive PAM DI pipe range?

If you’re interested in further details about Zinalium—including ideal ground conditions, performance properties, case studies, and more—Saint Gobain PAM, or our exclusive suite of ductile iron pipe products, please contact your local Clover team for more information or make an enquiry now.